Nov 24, 2009 (CIDRAP News) – The era of cell-based influenza vaccine production in the United States seemed to move closer today as Novartis unveiled its new, nearly billion-dollar manufacturing plant in Holly Springs, N.C., but onshore production and marketing of cell-based vaccines remains a few years away.

As the Swiss-based company held a ribbon-cutting ceremony at the plant today, it said the facility will be ready to start making the firm's vaccine adjuvant, MF59, as soon as next month, but the earliest it could start churning out flu vaccine is 2011, with full commercial production expected in 2013.

The plant, funded in part by the US Department of Health and Human Services (HHS), "is the first of its kind in the Untied States and highlights an important milestone in efforts to improve influenza vaccine manufacturing technology in the US and enhance domestic pandemic preparedness," the company said in a news release.

Novartis is one of five companies that were awarded large HHS contracts in 2006 to develop cell-culture technology for making flu vaccines. One of the other four contracts was terminated earlier this year, and a second company has put its efforts on hold.

Also, Sanofi Pasteur, which makes the largest share of seasonal flu vaccine in the United States and which received an HHS contract for cell-based vaccine development in 2005, says it is sticking with the traditional egg-based production.

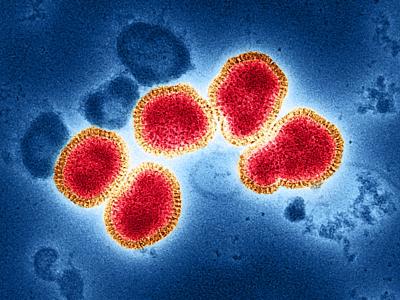

Cell culture technology—growing vaccine viruses in mammalian cells, such as canine kidney cells—is said to be more flexible and somewhat faster than the decades-old method of growing flu vaccines in chicken eggs. Cell-culture technology is used to make certain other vaccines, such as polio and rabies.

Experts such as Dr. Anthony Fauci, director of the National Institute of Allergy and Infectious Diseases, have said the technology will be an improvement but will not solve all the vexing problems of flu vaccine production, illustrated this year by the low initial yields of egg-based pandemic H1N1 vaccines.

In the Novartis announcement today, Chief Executive Officer and Chairman Daniel Vasella said, "We are proud to be one of the first companies to bring influenza cell culture as well as adjuvant technology to the United States. We have seen a great need to invest into new technologies for flu vaccines that will allow for quicker and more reliable production capacity."

The company statement said cell-based production operations "are cleaner, can be scaled up more quickly to respond to a pandemic, and do not rely on eggs for rapid response to a pandemic." No cell-based flu vaccine has yet been approved in the United States, but part of the firm's HHS funding will support the development of a vaccine for licensing, the company said.

"If licensed in an emergency, the facility will be ready to respond to a pandemic as early as 2011," the statement said. "The plant is planned to be running at full scale commercial production in 2013."

The facility is designed to produce 150 million doses of a pandemic flu vaccine within 6 months after declaration of a pandemic, officials said. The plant is slated to be capable of producing 50 million doses of trivalent seasonal flu vaccine per year.

Novartis has a plant in Marburg, Germany, that currently produces Celtura, a cell-based H1N1 vaccine that is licensed in Germany and Switzerland. The facility also makes a cell-based seasonal flu vaccine, Optaflu, which is approved in all 27 members of the European Union.

The Holly Springs facility can start making MF59 as early as December, Novartis officials said. No adjuvanted flu vaccines have been approved in the United States, but adjuvanted H1N1 vaccines are currently undergoing clinical trials. The most recent trials of an MF59-adjuvanted, cell-based H1N1 vaccine show that it elicits a protective immune response with a low dose, the company said.

A Novartis fact sheet says construction of the new vaccine plant "will continue into 2010." It also faces a long testing process before it can start producing, including more than 85 "factory acceptance tests," 400 commissioning protocols, and 650 qualification protocols. The facility currently employs 191 people full-time and will provide 350 skilled jobs when it is fully operational.

HHS awarded Novartis a $220 million contract in May 2006 to develop cell-based flu vaccines. Then in January of this year the agency announced a $487 million contract to help build the Holly Springs plant. Officials said HHS was bearing 40% of its cost. Today the company said the total investment in the plant is nearly $1 billion, including validation and licensing costs.

When the second contract was awarded, HHS officials said the North Carolina facility was expected to increase the US capacity to make pandemic flu vaccines by 25%.

Under the contract, Novartis will provide two flu vaccines for seasonal flu or for pre-pandemic use, according to HHS. The contract also will fund clinical studies to compare existing Novartis vaccines with new ones, including those developed in the new facility, to show that the new ones are also safe and effective, the agency said.

Other companies' efforts

Along with Novartis, four other companies received HHS contracts for cell-based vaccine development in May 2006: Solvay Pharmaceuticals, MedImmune, GlaxoSmithKline, and a partnership of DynPort Vaccine Co. and Baxter. The contracts totaled well over $1 billion. In addition, Sanofi Pasteur received a $97 million HHS contract for similar work in 2005. Some of the companies are continuing work under those contracts, while others have suspended the work or dropped it.

Sarah Alspach, a GlaxoSmithKline spokeswoman, said today the company is continuing its work under the $275 million contract, but she gave no details. "That work, which is still in early stages, is ongoing, and further details of the work and the contract are proprietary," she said. The work is being done at the company's facility in Marietta, Pa., she said.

Solvay Pharmaceuticals decided in 2008 not to pursue construction of a US cell-based vaccine facility, for several reasons, including the recession. That decision was followed by HHS's termination of the company's $298 million contract in June of this year, company spokesman Neil Hirsch told CIDRAP News today.

"While disappointed by HHS's action, the company remains committed to the development of cell-based influenza vaccine technology globally," he said.

The DynPort-Baxter partnership has completed several clinical trials of cell-based seasonal flu vaccines and a cell-based H5N1 vaccine, DynPort spokeswoman April L. Finnen said today, but she mentioned no plans for a US manufacturing facility. DynPort manages the overall project and the clinical trials, while Baxter makes the vaccines, according to previous company statements.

MedImmune, which makes nasal-spray seasonal and pandemic H1N1 flu vaccines, has put its cell-based development efforts on hold, Dr. George Kemble, the company's vice president for research and development, said today.

Kemble said the company has a disagreement with the Food and Drug Administration (FDA) over the direction of clinical trials for its cell-based flu vaccine. MedImmune officials were aiming to conduct trials to determine if cell-based and egg-based versions of the same vaccine were equally immunogenic, he said.

But the FDA said it wanted the company to proceed with an efficacy trial to determine if the cell-based vaccine actually protects people from seasonal flu. "That added years and hundreds of millions of dollars to the program," he said.

In view of the FDA's position, Kemble said MedImmune decided to "take a step back," reevaluate the program, and discuss it with HHS officials before deciding what to do next.

"We still see this as a very important development for flu vaccines . . . but to commercialize it is really challenging at this point," he said.

Meanwhile, Sanofi Pasteur has experimented with cell-based flu vaccines and concluded they offer little advantage, company spokeswoman Donna Cary said today.

Under its HHS contract, the company made a cell-based flu vaccine on a pilot scale and conducted several clinical studies, she said. "Our evaluation of phase 2 results indicated that while it worked and could be manufactured at a commercial scale, there was really no advantage in clinical performance," she added. "There might be a modest reduction in production time, but it would be expensive to produce."

Cary said Sanofi also studied the feasibility of building a cell-based vaccine plant. After that study, Sanofi and HHS agreed earlier this year that it made no sense to pursue the project, and they terminated the contract, she reported.

She said the company uses cell culture technology to make other vaccines and will continue to evaluate it for flu vaccines. However, she said, "We've seen only nominal advantages of cell culture over egg-based technology, which is proven and well tested."

In the current pandemic response, egg-based and cell-based facilities produced clinical lots of vaccine and achieved regular production in about the same amounts of time, Cary added.

At a congressional hearing earlier this month, Fauci of the NIAID said cell culture technology will be an improvement but will not be the final answer to flu vaccine production problems. He said the "end game" is to get away from vaccines that involve growing the virus and instead to produce particular viral proteins.

See also:

CIDRAP News story "Novartis gets US contract for cell-based flu vaccine plant"

July 18, 2006, CIDRAP News story "Novartis to build US cell-based flu vaccine plant"

May 4, 2006, CIDRAP News story "US awards $1 billion for cell-based flu vaccines"